08

Dec

Choosing between fabrication shops near me Toronto and on-site fabrication can make or break your project’s budget, timeline, and quality. Whether you’re planning structural steel repairs, custom metal fabrication, equipment modification, or industrial welding work, understanding the strengths of each method helps you make a smarter, cost-effective decision.

Fabrication Shop versus On-Site Fabrication: Which Is Better for Your Job?

This guide breaks down both options with practical examples, expert-backed insights, real job-site scenarios, and clear recommendations, so you can pick the approach that gets your project done right, the first time.

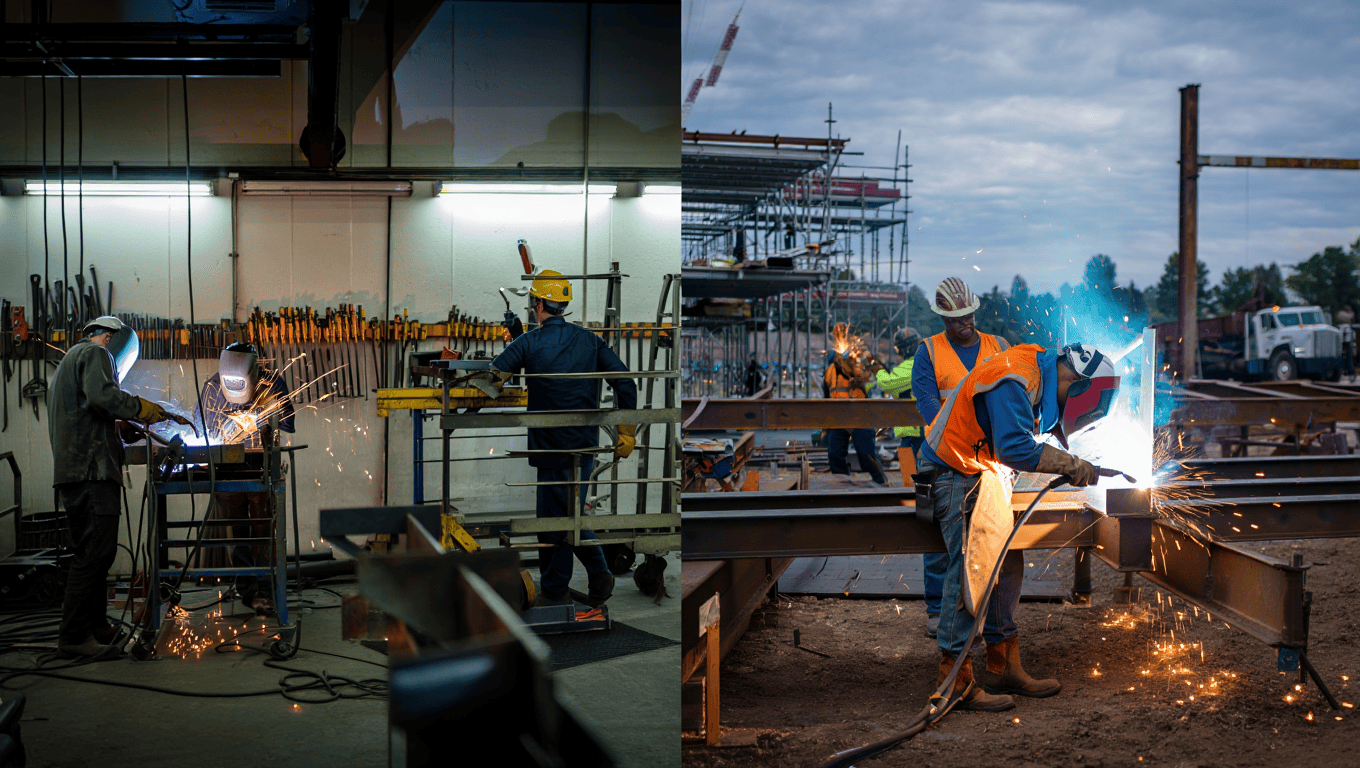

Fabrication Shop Welding

Work is completed at a fully equipped welding facility. In-shop fabrication typically have advanced tools, stable environments, and controlled conditions for precise fabrication.

On-Site Fabrication (Mobile Welding)

The welding team comes to your location, your home, job site, plant, warehouse, agricultural farm, or commercial facility, to complete repairs or fabrication work where the metal sits.

Both are essential. Both can deliver excellent results. The right option depends on your project’s size, complexity, accessibility, and urgency.

When Fabrication Shop Welding Makes More Sense

Fabrication shops excel in precision and production efficiency. If your project demands tight tolerances or advanced machinery, the shop environment usually wins.

Advantages of a Fabrication Shop

1. Controlled Environment for Better Weld Quality

Shops eliminate variables like wind, rain, debris, humidity, or temperature swings, factors that can weaken welds or cause defects.

2. Access to High-End Welding Machinery

Examples include:

- CNC plasma tables

- Press brakes

- MIG, TIG, and multi-process machines

- Industrial cutting tools

- Material handling equipment

These tools allow for:

- Tighter tolerances

- Faster production

- Higher repeatability

- Better overall finish

3. Cost Efficiency for Large Batches

If you need:

- Multiple identical parts

- Custom components

- Structural steel assemblies

- Cut, bent, rolled, or machined pieces

…a fabrication shop can produce them faster and cheaper.

4. Higher Level of Testing and Inspection

Shops can perform:

- Non-destructive testing (NDT)

- Weld inspections

- Dimensional checks

- Quality assurance documentation

These are vital for commercial, industrial, and municipal projects.

When On-Site Fabrication (Mobile Welding) Is the Better Option

On-site fabrication shines when speed, convenience, and real-world practicality matter most.

Advantages of On-Site Welding

1. Zero Downtime and No Transport Hassle

If your equipment, gate, railing, or structural support is stationary or too heavy to move, on-site welding saves hours, sometimes days, of downtime.

Common examples:

- Broken heavy machinery

- Damaged handrails or safety guards

- Cracked frames

- Structural steel reinforcement

- Construction site modifications

2. Ideal for Emergency Repairs

According to industry averages, equipment downtime can cost businesses anywhere starting $200 per hour, depending on the sector. A mobile welder arriving the same day, sometimes within hours, can prevent major losses.

3. Real-World Fit-Up

Sometimes a part must be welded to match existing structures.

Bringing it to a shop won’t help if the reference points are on-site.

On-site welding eliminates:

- Alignment issues

- Measurement errors

- Rework due to poor fit

4. Perfect for Small, Quick Jobs

If the repair or fabrication is minor, you’ll waste more time transporting the piece than fixing it.

Think:

- A small crack

- A broken bracket

- A loose hinge

- A simple reinforcement

A mobile welder can fix these in minutes.

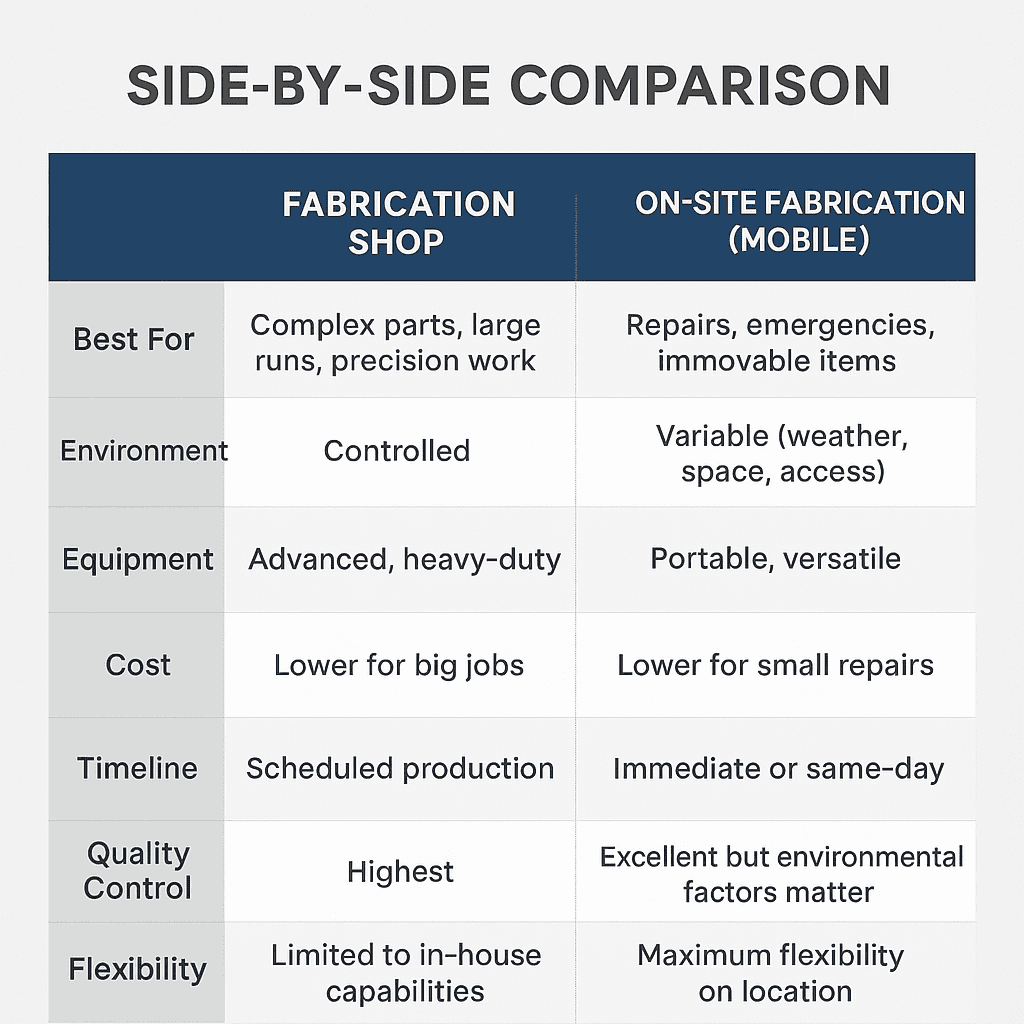

Side-by-Side Comparison Table

| Feature | Fabrication Shop | On-Site Fabrication (Mobile) |

|---|---|---|

| Best For | Complex parts, large runs, precision work | Repairs, emergencies, immovable items |

| Environment | Controlled | Variable (weather, space, access) |

| Equipment | Advanced, heavy-duty | Portable, versatile |

| Cost | Lower for big jobs | Lower for small repairs |

| Timeline | Scheduled production | Immediate or same-day |

| Quality Control | Highest | Excellent but environmental factors matter |

| Flexibility | Limited to in-house capabilities | Maximum flexibility on location |

Cost Breakdown – Which Option Saves You More Money?

The right choice depends on project size.

Tasks That Are Typically Cheaper in a Shop

- Fabricating multiple identical steel components

- CNC-cutting steel plates

- Bending and forming metal

- Welding stainless steel or aluminum with clean finish requirements

- Production-level fabrication

Tasks Cheaper On-Site

- Quick structural repairs

- Gate, fence, railing fixes

- Emergency welding

- Heavy equipment repairs

- Anything too large to transport

A simple guideline:

If it fits in a pickup truck and needs precision, shop.

If it’s welded to the earth, on-site.

Expert Insight: What Professionals Recommend

Welding Pro Tip #1

Shop welding produces the most consistent results because environmental conditions stay the same from start to finish.

Welding Pro Tip #2

On-site welding is often the only practical choice for structural steel. Removing beams or columns is nearly impossible once installed.

Welding Pro Tip #3

Never choose on-site welding for aluminum unless absolutely necessary. Aluminum requires clean, contaminant-free conditions, something shop environments handle better.

Real-World Examples

Example 1: Commercial Handrail Repair

A hotel’s staircase handrail cracked due to corrosion. Moving it to a shop would shut down the staircase for a day.

On-site welding fixed it within an hour.

Example 2: Custom Bracket Fabrication

A manufacturing plant needed 60 identical brackets for a conveyor system. Shop welding allowed precise, fast production.

Fabrication shop saved them 40% in labour.

Example 3: Excavator Bucket Crack

An excavator on a construction site fractured during digging.

Bringing it to the shop? A logistical nightmare.

Mobile welding had it back in service the same afternoon.

Ready to Get Your Welding Job Done Right?

If you’re unsure whether your project needs shop fabrication or on-site welding, reach out for expert guidance. A quick conversation can save you time, money, and costly mistakes. Explore your options, compare solutions, and get professional advice tailored to your exact project needs.

When you’re ready for high-quality welds, whether in a fully equipped shop or at your doorstep, reach out and get the job done with confidence.

If you’d like, I can also create a GMB post, social snippet, meta description, or FAQ schema for this blog.

FAQs

Is shop welding stronger than on-site welding?

Generally yes. Controlled temperature, cleanliness, and tooling help produce more consistent welds.

Is mobile welding more expensive?

It can be slightly higher per hour, but usually cheaper overall for quick repairs because you avoid transportation costs and downtime.

Can mobile welders handle structural steel?

Absolutely, especially for reinforcement, repairs, or modifications. Many field welders are certified for structural work.

What can’t be done on-site?

CNC cutting, large bending, advanced machining, and complex aluminum fabrication typically require a shop.

When should I choose on-site welding?

When the material is too heavy to move, when speed matters, or when fit-up depends on real-world alignment.

Final Verdict , Which Is Better?

There’s no universal winner.

Fabrication shops excel in precision, production, and finish quality.

On-site fabrication dominates repairs, emergencies, and real-world fit-ups.

The right choice depends on:

- Project size

- Urgency

- Material type

- Environment

- Accessibility

- Budget

Most businesses and homeowners end up needing both at different times. Not sure which services is rightr or you?

Speak to our experienced welder today. (416)-825-2956.