09

Dec

Absolutely – here is the fully Canadian-optimized version of the blog post, professionally adapted for Canadian climates, regulations, terminology, and welding standards.

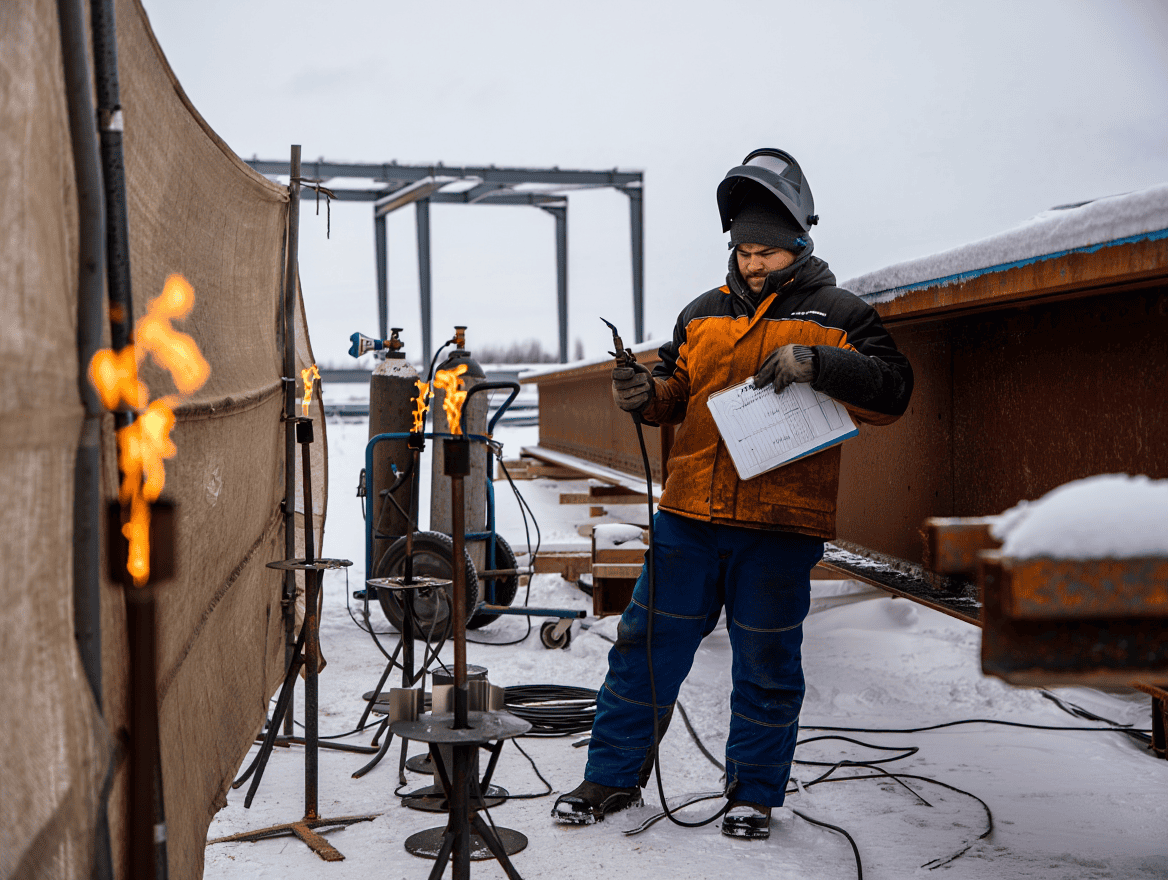

Welding in Canada isn’t just about skill-it’s about battling snow, wind chill, icy steel, and unpredictable weather conditions that can shift within hours. Whether you’re welding in Alberta’s deep freeze, tackling structural repairs in Ontario, or managing fabrication work in coastal BC, cold temperatures can dramatically affect weld strength, metal behaviour, and job-site safety.

This guide walks you through everything Canadian welders must do before striking an arc in winter. It’s tailored to Canadian climates, incorporates CSA standards, and includes practical checklists, real-world insights, and essential cold-weather welding best practices.

Why Welding in Canadian Winters Requires Special Preparation

Canada’s climate pushes metals and equipment past their limits:

- Steel becomes brittle at sub-zero temperatures

- Moisture from snow, frost, and condensation increases hydrogen-induced cracking

- Wind chill interferes with shielding gases

- Equipment struggles when stored outside overnight

- CSA standards require stricter controls compared to mild-weather regions

According to the Canadian Welding Bureau (CWB), cold weather contributes to a spike in structural cracking and porosity failures across winter job sites-most of them traced back to improper surface prep, poor preheat control, or moisture contamination.

Cold Weather Welding Prep Checklist for Ontario, Canada

Below is your complete Canadian winter prep workflow.

1. Evaluate the Canadian Job-Site Environment

Monitor Temperature (CSA Requirements)

CSA W59 requires minimum steel temperatures before welding. As a general rule:

- 0°C (32°F) minimum for most structural welding

- Higher minimums apply for thicker or high-strength steels

Low temperatures increase hardness and cracking risk-especially in the Prairies where metal can drop to -30°C.

Check Wind Chill

Strong wind is common across Canada-especially in open industrial job sites.

- Shielding gases destabilize above 5-10 km/h wind

- Use windbreaks or switch to SMAW/FCAW-S when outdoors

Remove Snow, Frost & Ice

You’ll see condensation even on “dry-looking” steel-especially on cold mornings. Use:

- Propane heaters

- Salmander heating units

- Preheat blankets

- Insulated welding tents

Never weld on steel that is frosty to the touch.

2. Identify the Material and Required CSA Preheat Levels

Cold temperatures accelerate cracking, so preheat becomes non-negotiable.

Typical Preheat Ranges (CSA W59-Based Guidance)

| Material | Thickness | Preheat Range |

|---|---|---|

| Mild/Carbon Steel | < 13 mm | 50-150°C |

| High-Strength Steel | > 13 mm | 150-260°C |

| Structural Steel (W59) | Varies | Follow Table 5 & WPS |

| Cast Iron | Any | 260°C+ mandatory |

In Canada’s winter conditions, preheat requirements may increase by 10-20% to counter rapid heat loss.

3. Clean and Dry the Metal Surface Thoroughly

Winter job sites create the perfect storm of contamination:

- Road salt

- Ice crystals

- Condensation

- Wind-blown snow

Before welding:

- Grind off rust, paint, and coatings

- Remove ice mechanically

- Preheat to evaporate absorbed moisture

- Verify temperature with a contact thermometer or IR gun

If the metal feels cold or damp-it needs more heat.

4. Protect and Precondition Consumables (Critical in Canada)

Low-Hydrogen Rods (e.g., E7018)

CSA W59 requires low-hydrogen electrodes to be stored in heated ovens.

- Keep at 120°C-150°C

- Reheat if exposed to cold air for too long

- Never leave rods in an unheated truck overnight

Wire Spools

Cold wire causes feeding issues-warm them up indoors before use.

Shielding Gas Cylinders

Canadian winters can cause:

- Pressure drops

- Unstable flow

- Water vapour contamination

Store cylinders inside a sheltered, above-freezing, upright area.

Flux Materials

Flux absorbs humidity quickly-store in sealed, heated storage.

5. Prepare Your Welding Equipment for Sub-Zero Temperatures

Canadian welders know: cold kills machines faster than anything else.

Warm Up the Machine

Allow 10-20 minutes of warm-up time. Cold power sources lead to:

- Erratic arc starts

- Voltage fluctuations

- Dropping duty cycles

Inspect Cables & Hoses

Cold rubber becomes stiff and brittle. Check for:

- Cracking

- Stiff leads

- Exposed copper

- Frozen moisture inside hoses

Adjust Gas Flow

Increase slightly (but avoid turbulence) if welding outdoors or near open areas.

6. Improve Worksite Conditions (Canadian Winter Edition)

Use Welding Tents or Tarps

A must-have for outdoor work in provinces with strong winds.

Add Job-Site Lighting

Short winter days = poor visibility.

Keep the Area Dry

Snow melt creates a slipping hazard and contaminates welds.

Use Portable Heaters Safely

Always direct heaters away from the weld zone to avoid turbulence in shielding gases.

7. Preheat Properly (Canada’s Most Important Step)

Canadian winters pull heat out of steel fast-especially under windy conditions.

Best Preheat Methods

- Induction heating (CSA-approved)

- Oxy-fuel torches

- Electric blankets

- Salamander heaters

- Infrared heaters

Verify Temperature Across the Entire Joint

Ensure:

- Even heat distribution

- Minimum CSA-required temperature

- Consistent temperature between passes

Expert Insight (Canada): “Cold cracks are preventable 99% of the time. The secret is controlling moisture and temperature-especially on Prairie job sites.” – CWB Level 2 Welding Inspector, Calgary, AB

8. Adjust Your Welding Technique for Winter

Technique Tips

- Use stringer beads (not wide weaves)

- Shorten arc length

- Slightly increase travel speed

- Maintain interpass temperature above minimum WPS requirements

- Use multiple passes for thick material

Best Processes for Canadian Winter

- SMAW (Stick Welding) – Reliable in cold and windy conditions

- FCAW-S – Excellent for outdoor structural work

- MIG – Best indoors or inside heated tents

- TIG – Only in controlled, indoor environments

9. Control the Cooling Rate After Welding

Rapid cooling is especially dangerous in cold climates like Saskatchewan or Northern Ontario. Use:

- Thermal blankets

- Insulated covers

- Slow cool-down periods

For high-strength or critical structural welding jobs (common in Canadian construction), post-weld heat treatment may be required.

10. Document All CSA Compliance Requirements

For Canadian projects, you may need:

- CWB welder qualifications

- CSA W59-compliant preheat logs

- Inspection reports

- Welding Procedure Data Sheets (WPDS)

- Material certifications

- Environmental condition records

Proper documentation ensures safety and adherence to provincial building codes.

Canada-Ready Cold Weather Welding Checklist (Quick Version)

✔ Minimum steel temperature meets CSA requirements

✔ Snow, frost, and ice fully removed

✔ Metal cleaned and dry

✔ Consumables warmed and stored correctly

✔ Machines warmed and cables inspected

✔ Windbreaks or welding tents in place

✔ Preheat applied and verified

✔ Technique adjusted for winter conditions

✔ Cooling controlled

✔ CSA documentation completed

Final Thoughts: Welding Strong in Canadian Winters

Cold-weather welding in Canada isn’t just “regular welding but colder.” It’s an entirely different operating environment-one that demands more preparation, stricter controls, and deeper awareness of how climate affects metallurgy. Follow above Canadian-specific checklist, and you’ll produce safer, stronger, more durable welds no matter how cold it gets.

FAQs: Cold Weather Welding in Canada

1. Can you weld below freezing in Canada?

Yes, if you follow CSA preheat requirements and eliminate moisture.

2. What is the best welding method for Canadian winter work?

Stick welding or flux-core (self-shielded) work best outdoors.

3. Do you need to preheat steel in Canadian winter?

Almost always. Cold metal dramatically increases cracking risk.

4. Is welding outdoors safe during a snowstorm?

No. Snow, moisture, and strong winds compromise weld integrity and safety.

5. Do Canadian building codes affect welding requirements?

Yes, CSA standards (W59, W47.1) govern structural welding practices nationwide.

When the temperature drops and the risks rise, the smartest move is trusting a certified professional. Experienced welders know how to manage cold-weather challenges, apply the right techniques, and ensure every joint meets strict safety and quality standards.

If you want the job done right the first time, strong, clean, and built to last—hire a qualified welding professional and protect your project from costly winter mistakes.

Call (416)-825-2956, or contact us for free cost estimate.