17

Feb

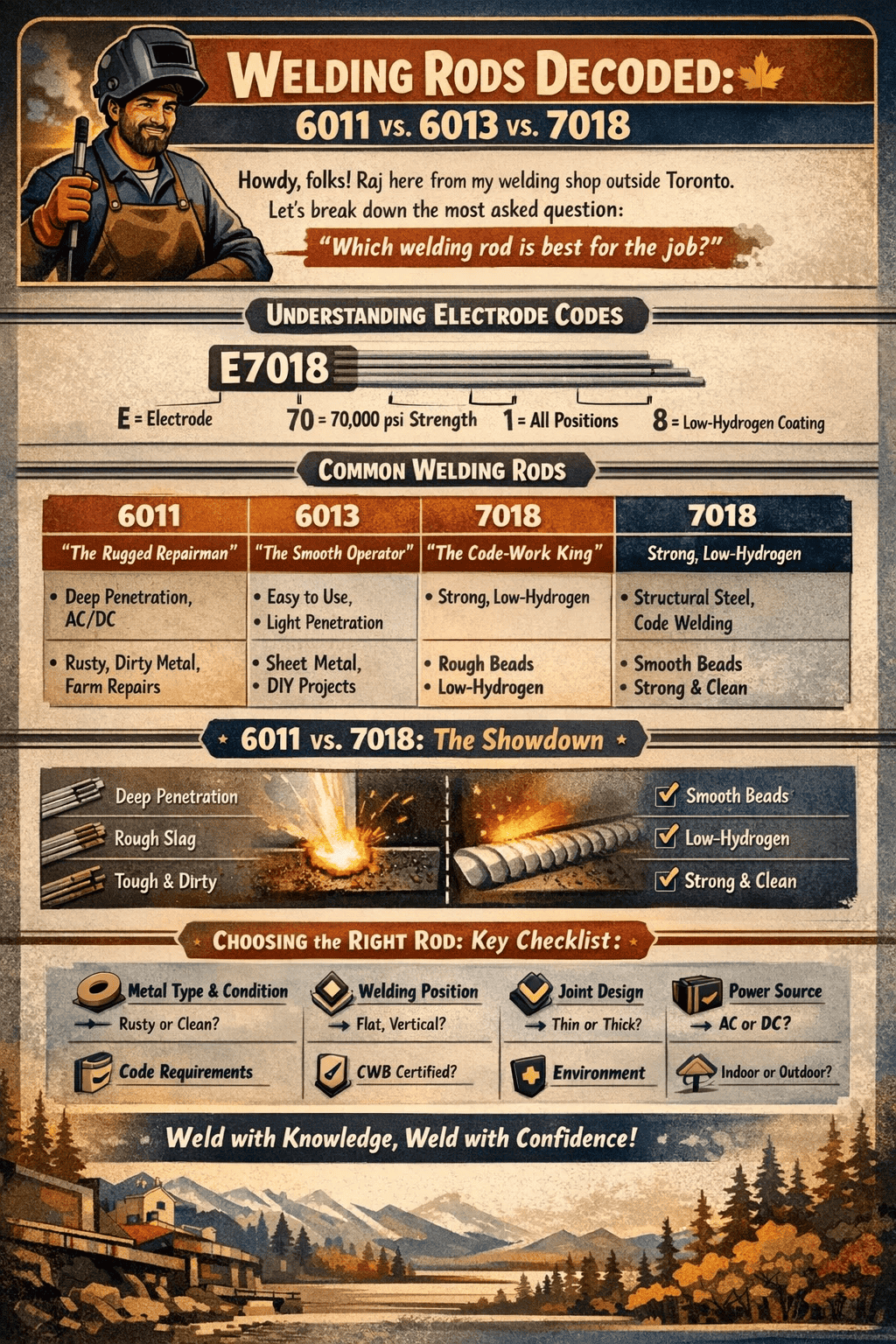

Howdy, folks. Raj here, from my welding shop just outside Toronto. Over nearly two decades under the hood, I’ve bent, burned, and busted more welding rods than I can count, from -40°C pipeline tie-ins in Fort McMurray to intricate fabrication in Toronto shops. And if there’s one question I get asked most, by apprentices and seasoned hands alike, it’s this: 6011, 6013 or 7018 welding rod “Which rod is best for this job?”

Choosing the right welding rod isn’t just shop trivia; it’s the difference between a weak, crack-prone joint and a strong, clean, X-ray quality weld. It’s also about safety, integrity, and pride in your craft. Whether you’re tackling a farm gate repair in Saskatchewan, a custom fabrication in B.C., or preparing for your Red Seal exam, this guide will give you the plain-spoken, professional know-how to confidently select and use the most common welding rods in Ontario, Canada.

What is a Welding Rod and How is it Classified?

A welding rod, formally called a shielded metal arc welding (SMAW) electrode, is a metal wire coated in flux. When you strike an arc, the rod melts, depositing filler metal into the weld joint. The flux coating vaporizes, creating a protective gas shield and forming a slag layer, both of which protect the molten weld pool from contaminants in the air, like oxygen and nitrogen, that can cause weakness and defects.

In Canada, we primarily use the CSA (Canadian Standards Association) W48 classification system. While it is heavily harmonized with the American Welding Society (AWS) system, the Canadian Welding Bureau (CWB) specifically certifies consumables and welders to the CSA standards. That four or five-digit code on your electrode box isn’t random; it’s a detailed data sheet.

How to Read an Electrode Code (e.g., E7018)

- The letter “E”: Stands for Electrode.

First two digits (“70“): Indicate the minimum tensile strength of the weld metal in thousands of pounds per square inch (psi). An E7018 welding rod has a 70,000 psi minimum tensile strength. This is a critical spec for structural and pressure vessel work governed by CWB and ASME codes.

- Third digit (“1”): Tells you the welding positions it’s approved for.

- 1 = All positions (Flat, Horizontal, Vertical, Overhead)

- 2 = Flat and Horizontal positions only

- 3 = Flat position only

- Last digits (“8“): This is the key. It describes the flux coating type and the welding current (AC or DC) to use. The coating dictates the arc characteristics, penetration, and slag behavior.

Below are Common Welding Rod Types and Their Uses

Let’s get into the workhorses of the welding industry. Here’s a practical table, then we’ll break each one down.

| Code | Nickname | Key Characteristics | Best For | Common Uses in Canada |

|---|---|---|---|---|

| E6010 | The Digger | Deep penetration, cellulose coating, DC only. Fast-freeze slag. | Root passes on pipe, dirty/rusted metal, deep penetration needs. | Pipeline welding, shipbuilding, structural steel where backside cleaning is possible. |

| E6011 | The All-Position AC Rod | Similar to 6010 but runs on AC or DC. Good penetration. | General repair, farm equipment, when you only have an AC machine. | Maintenance welding, contractors using AC buzz boxes, outdoor windy conditions (it’s less sensitive to wind than some). |

| E6013 | The Easy Starter | Light penetration, smooth arc, easy slag removal. AC/DC. | Sheet metal, thin gauge steel, novice welders, artwork. | Light fabrication, auto body repair (thin metal), DIY projects, ornamental iron. |

| E7018 | The Low-Hydrogen Champion | Iron powder, low-hydrogen coating. Very smooth, strong, ductile welds. | Structural steel, critical joints, high-strength applications, anything requiring high impact resistance. | CWB code work, buildings, bridges, pressure vessels, and in high-stress or cold weather applications. |

| E7024 | The Fast-Fill Rod | High deposition, iron powder coating. AC/DC. | High-speed, flat fillet welds on thick, clean material. | Production welding in the flat/horizontal position—think barge building, large beam seams. |

Exploring 6011, 6013, and 7018 Their Uses

E6011 Welding Rod: The Rugged Repairman

“When you don’t know what’s under that paint or grime, a 6011 rod will burn through and tell you,” as my old journeyman used to say. It’s my go-to for questionable metal. It has a forceful, digging arc that can handle rust, mill scale, and dirt better than most. The difference between 6010 and 6011 is crucial: 6010 is DC-only and preferred for downhill pipe. while 6011 runs on AC or DC, making it the versatile choice for the classic AC transformer welder still found in many Canadian garages and farms. Use it for general repair, but expect a rougher bead profile and more spatter than a 7018.

E6013 Welding Rod: The Smooth Operator

If 6011 is a chisel, 6013 is a fine brush. It produces a soft, stable arc with minimal spatter and very easy-to-remove slag. Its shallow penetration is a double-edged sword: it’s excellent for thin material where burn-through is a risk, but it’s not suitable for critical structural joints on thicker material due to lack of fusion concerns. It’s the best welding rod for beginners because it’s forgiving and runs nicely on inexpensive AC machines. Perfect for sheet metal work, trailer panels, and non-critical repairs.

E7018 Welding Rod: The Code-Work King

This is the rod for when it has to hold. The ‘low-hydrogen’ designation is key. Hydrogen is the primary cause of cracking in welds, especially in thick sections or cold climates. The 7018’s coating is baked to minimize moisture. *It must be stored in a proper electrode oven (around 250°F/120°C) if the package has been opened*, especially in humid Canadian summers. It produces beautiful, smooth beads with a dense slag that peels off like a dream. The weld metal is exceptionally strong and ductile, meaning it can withstand impact and flexing, vital for seismic zones or heavy-loaded structures.

Understanding Key Difference Between 7018 and 6011 Welding Rod

This is the most common comparison I hear. Let’s me explain it.

- Penetration & Arc: 6011 has a digging, aggressive arc with deep penetration. 7018 has a smooth, stable, “buttery” arc with medium penetration.

- Slag & Bead: 6011 has a rough, hard-to-clean slag and a rippled bead. 7018 has an easy-to-remove slag and a smooth, clean, “stacked dimes” look.

- Strength & Use: 6011 is for penetration and dirty metal. 7018 is for ultimate strength and quality finishes. You might use a 6011 for a root pass on a thick, beveled joint because it digs in, then cap it with 7018 for strength and appearance.

- Storage: 6011 is relatively hardy. 7018 is moisture-sensitive and requires strict storage protocols for code work.

How to Choose the Right Welding Rod? A Useful Checklist for Canadian Welders

Don’t just grab what’s on sale. Run through this list:

- Check for Base Metal Type & Condition: Is it clean mild steel, rusty A36, or something else? Match the rod to the metal. For dirty/rusted metal, a 6011 is your friend.

- Welding Position: Working overhead or vertical? Ensure your rod’s third digit is ‘1’ (all-position).

- Joint Design & Penetration Need: A thin lap joint on sheet metal? 6013. A thick, single-V groove joint? You’ll likely need the penetration of a 6010/6011 for the root, then fill with 7018.

- Power Source: Check your welder! AC only? Eliminate 6010 and 7018 (unless your machine has DC capability).

- Code & Specification Requirements: Is this a CWB-tested procedure or a non-critical repair? For any structural, pressure, or public-use fabrication, you MUST follow the specified Welding Procedure Specification (WPS). No shortcuts.

- Environmental Conditions: Working outside in a Manitoba wind? Low-hydrogen rods like 7018 are more sensitive to drafts. You may need wind blocks.

Pro Tips and Best Practices from the Shop

- Storage is Non-Negotiable: I keep my personal 7018s in a portable oven. For hobbyists, buy in small, sealed containers and use a plastic storage container with silica gel packs. Once a low-hydrogen rod is exposed to air for too long (a few hours in high humidity), it must be re-dried in an oven per manufacturer specs.

- Read the Datasheet: The manufacturer’s guide on the side of the box gives you the exact amperage range, drying temperatures, and other critical info. Use it.

- Practice on Scrap: Before starting a critical weld, dial in your amperage and technique on an identical piece of scrap metal. It saves heartache.

Weld with Knowledge, Weld with Confidence

Understanding welding rods transforms you from someone who just makes sparks to a craftsman who makes intentional, durable decisions. It’s the foundation of SMAW welding. Start with the basics, respect the rods, especially the moisture-sensitive ones, and never stop practicing.

Ready to Put This Knowledge to Work?

- For the Hobbyist & DIY Warrior: Head to your local Canadian welding supply store with this guide in hand. Talk to their experts, pick up a small box of 6013 and 7018, and get some scrap to practice on. Feel the difference.

- For the Apprentice & Professional: Dive deeper. Study the CWB standards and AWS handbooks. Your expertise in electrode selection is a direct measure of your professional value.

- Need Certified Work Done? If your project requires CWB-certified welding, be it a structural beam for a deck, a critical repair on equipment, or a custom fabrication, hire a CWB-certified welder near you. It ensure safety and quality of work.

FAQ: Your Welding Rod Questions, Answered

Q: What is the best all-around welding rod for a beginner in Canada?

A: For a beginner with a common AC/DC inverter machine, start with an E6013. It’s forgiving on amperage, easy to strike, and the slag practically lifts off itself. Once comfortable, graduate to E7018 to understand the feel of a true low-hydrogen rod.

Q: Can I weld 7018 on AC current?

A: Yes, modern 7018 electrodes are designed to run on both AC and DC. However, they run supremely smooth on DC reverse polarity (electrode positive). You’ll get a more stable arc and easier restrikes on DC.

Q: Why do my 7018 rods keep sticking or the flux is cracking?

A: Moisture. This is almost always the issue. If a 7018 rod has absorbed moisture from the air, the flux becomes brittle and the arc becomes unstable. Ensure proper storage. Also, ensure your amperage is high enough, a too-cold arc will cause sticking.

Q: What rod should I use for welding old, rusty steel like on my snowplow frame?

A: Grab your E6011. Its deep, penetrating arc can burn through light rust, paint, and contamination. Just chip and wire-brush off as much loose scale as you can first for the best results.

Q: Is there a big difference between brands of the same rod type (e.g., Lincoln Excalibur 7018 vs. Hobart 7018)?

A: While the AWS spec ensures minimum performance, there are subtle differences in arc feel, slag behavior, and moisture resistance between premium brands. Most pros develop a personal preference. For hobbyists, focus on buying from a reputable supplier (like Praxair, Air Liquide, or a trusted local welding supplies store) to ensure you’re getting fresh, genuine product.