05

Dec

Any fabrication shop might have a handful of common factors like a familiar chorus, grinders humming, metal clinking, torches hissing like irritated cats. But somewhere in the corner, contradicting the deafening noise, there’s usually a quieter workstation where the welds look as if they were drawn with a silver-tipped fountain pen. That’s the TIG station. And the person running it is either a wizard… or someone who’s spent years developing a steady hand while dealing with sensitive areas of welding.

What is TIG Welding?

TIG welding, short for Tungsten Inert Gas welding, isn’t actually a rowdy, high-speed sibling of the welding family. It’s the introverted one who shows up to every job with meticulous focus and the patience and silence of a monk.

But what exactly is TIG welding used for? And why do so many fabrication shops swear by it?

Let’s break it all down, one bead at a time.

TIG Welding and Its Magic: which is better MIG or TIG welding?

Unlike MIG welding, where the machine basically hands you a wire buffet, TIG welding requires you to dance with fire a little differently. One hand controls the torch, the other feeds filler metal, and your foot taps the pedal like you’re tuning an old hot rod carburetor.

This method gives welders an exceptional level of control. And that kind of precision opens the door to industries where rough edges simply aren’t acceptable.

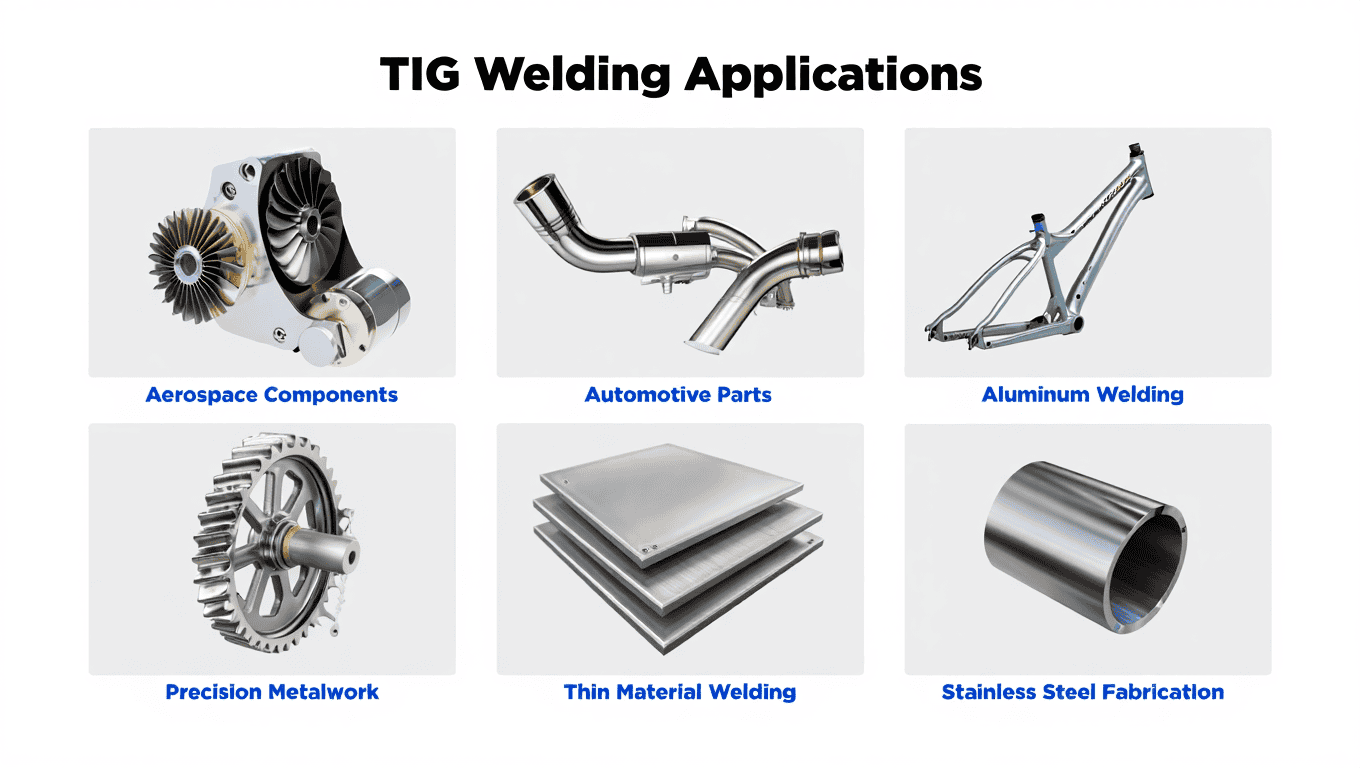

Common applications where TIG welding is used:

Here’s when you should use TIG welding

1. Custom Fabrication and Architectural Metalwork

If you’ve ever seen a stainless steel countertop so smooth it reflects light like a mirror, odds are an efficient TIG Welding services provider played a big role in its creation. TIG is the go-to choice when aesthetics matter more than brute force.

You’ll find TIG welds in:

- Decorative metal panels

- High-end stair railings

- Custom gates and artwork

- Sculptures and structural designs where seams need to be beautiful

TIG welds rarely need grinding, polishing, or cleanup. They’re the neat freaks of fabrication.

2. Aerospace and Aviation Work

Aerospace engineers love TIG welding the way car guys love chrome. It’s strong, it’s incredibly precise, and it can work with metals that demand extra respect.

Metals commonly used in aircraft components:

- Titanium

- Aluminum

- Magnesium alloys

- Stainless steel

These high-performance materials don’t tolerate sloppy heat control. Too much heat, and you compromise durability. Too little, and you get weak bonds. That’s why TIG welding sits firmly at the top of the aviation food chain — it delivers strength without distortion.

From engine parts to structural supports, TIG welding helps keep aircraft safe, lightweight, and engineered for the clouds.

3. Automotive Fabrication and Restoration

Hot rod builders, custom exhaust fabricators, and restoration pros all have a soft spot for TIG welding. It gives them the flexibility to work with thin metals without blowing holes through vintage car panels.

TIG welding is widely used for:

Aluminum and stainless exhaust systems

- Roll cages

- Fuel tanks

- Chassis modifications

- Bodywork repairs on classic vehicles

If MIG welding is a sledgehammer, TIG welding is the scalpel. And in automotive restoration, precision isn’t optional — it’s survival.

4. Food-Grade and Sanitary Fabrication

Food processing facilities, breweries, and pharmaceutical labs, these places don’t mess around with cleanliness. TIG welding shines here because it creates ultra-smooth, crevice-free welds that bacteria can’t cling to.

Typical TIG-friendly equipment includes:

- Stainless steel piping

- Restaurant kitchen equipment

- Conveyor systems

- Brewery tanks and kettles

Every TIG bead in these applications needs to be pristine and uniform, because one contaminated weld can shut down an entire production line.

5. Pipe Welding and High-Pressure Systems

TIG welding is trusted for pipelines or systems where failure isn’t an option — think chemical plants, refineries, nuclear installations, or high-pressure steam lines.

Advantages of TIG Welding

- Because it offers:

- Minimal contamination

- Controlled penetration

- Stronger, more reliable joints

These environments don’t just need welders; they need artisans who understand metallurgy like chefs understand knives.

6. Repairs, Refinishing, and Delicate Fixes

Sometimes you need to repair something without making it look like it battled a lawn mower. TIG welding excels at delicate fixes:

- Cracked aluminum housings

- Thin brackets

- Intricate metal components

- Motorcycle frames

- Antique metalwork

With TIG, welders can dial the heat down to whisper-level, giving them room to finesse a repair instead of overwhelming it.

Why So Many Welding and Fabrication Shops Rely on TIG

TIG welding isn’t the fastest process. It’s not the cheapest either. But when customers want something built with surgical precision, TIG is the answer.

- Fabrication shops rely on it because:

- It works with nearly every weldable metal

- It leaves extremely clean, visually striking welds

- It offers unmatched control over heat and filler

- It minimizes distortion

- It allows welders to handle intricate designs

- It avoids sparks, spatter, and other messy by-products

- In short, if the job demands finesse, TIG takes the spotlight.

Is TIG Welding Right for Your Project?

As far as deciding whether TIG welding is the right match for your next project, the answer reveals itself through the demands of the work. When your creation calls for durability woven with visual distinction, when it insists on exact tolerances that leave no wiggle room, or when the metals in question belong to the more temperamental corners of metallurgy, TIG often becomes the obvious choice.

FAQs

Why is TIG welding more complex?

TIG welding can deal with materials that are thin and delicate and require more precision.

What materials can TIG welding join?

The TIG method can be used on aluminum, stainless steel, titanium, magnesium alloys, and even certain copper-based materials.

Which method delivers visually pleasing results?

TIG welding is the process that ensures visually appealing joints.

How to avail high-quality TIG welding services without commuting to the workshop?

RS mobile is much more than capable of designing functional and strong welds for any industry or sector.

How to contact RS Mobile for welding?

Call us at (416)-825-2956 to avail all welding and fabrication-related services. Search TIG Welding near me in Mississauga or sourrinding areas in GTA to avail the same.