07

Nov

Welding, the process, while it is always advised to cover your eyes with proper protection, obviously makes your brain relate extreme heat to it. The danger of molten metal and flying sparks can harm the eye or cause burn accidents. Compared to this, there is a less risky welding process too. a process that binds without flame, that forges without melting. It’s called cold welding, and it stands like a quiet rebellion against the roaring heat of conventional welding.

No sparks. No sizzle. Just silence and somehow, an almost magical molecular handshake that fuses two metals into one. It feels less like industry and more like alchemy with a scientific accent.

What is cold welding?

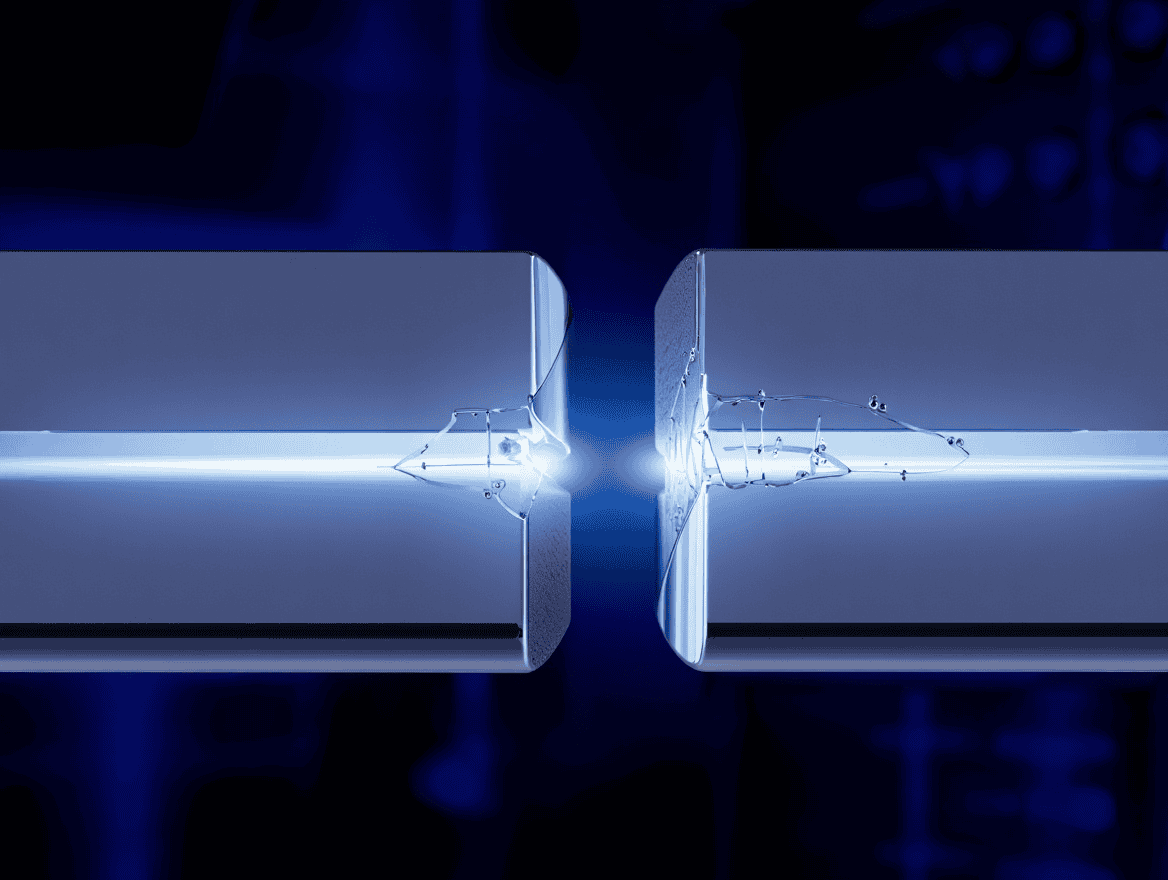

Cold welding, sometimes whispered about as contact welding or solid-state bonding, is the art of joining metals without ever letting them liquefy. There’s no melting pool, no fiery arc; instead, it relies purely on pressure and purity.

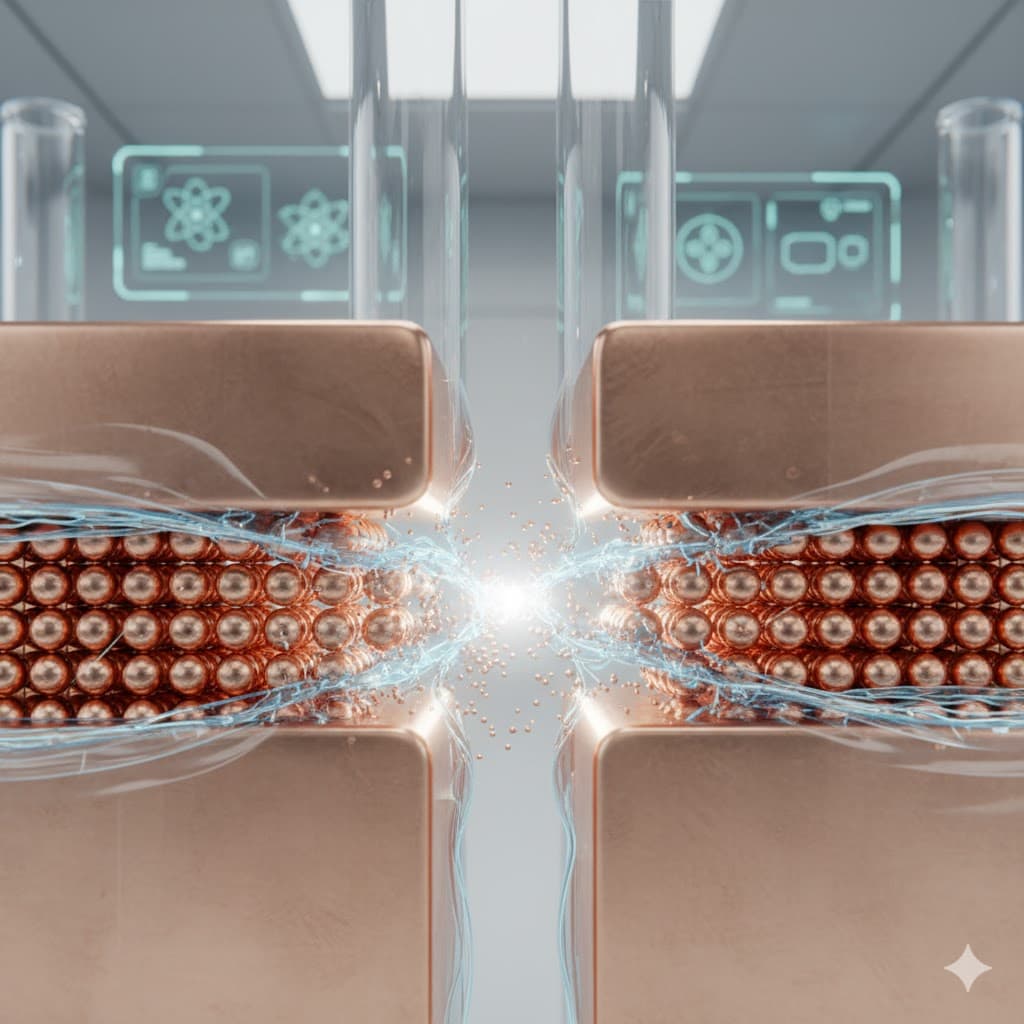

When two flawless metallic surfaces meet under the right amount of force, their atoms begin to lose all sense of separation. The boundary between them fades until what was once “two” becomes “one.” It’s atomic amnesia but beautiful.

However, this seamless union has one sacred rule: the surfaces must be immaculate. Even a microscopic film of oxide, oil, or dust will act like a wall, keeping atoms from linking. That’s why cold welding doesn’t just happen when two metals touch; the contact has to be perfect, down to the atomic level. Strip away every impurity, and those metals behave like long-lost kin recognizing each other again.

Cold Welding Explained

Inside every metal, atoms sit in a tidy crystalline arrangement; a grid of metallic order. When two perfectly clean metallic faces are forced together under intense pressure, those atomic grids collapse into one another. The atoms stop recognizing where one lattice ends and the next begins.

The result? A single, continuous metallic structure that has no visible joint. No filler. No seam. No trickery. Just atomic intimacy.

That’s what makes cold welding so mind-bending: it achieves the permanence of traditional welding without a single flicker of flame.

Metals That Obey the Law of Cold Welding

Not every metal has the temperament for this process. Cold welding loves ductile metals — those that can yield and deform rather than crack or crumble. The all-stars include:

- Aluminum and its silvery siblings

- Copper

- Gold and silver (yes, even precious metals play along)

- Nickel

- Lead

Tough, brittle metals like cast iron or hardened steel? They’re the stubborn ones, prone to fracture under pressure, not flexibility.

Interestingly, cold welding doesn’t shy away from mixing and matching. Unlike fusion welding, which often balks at pairing dissimilar metals, cold welding excels at it.

Since no melting occurs, there’s no thermal warping or awkward chemical incompatibility. It’s like diplomacy at the atomic level, seamless cooperation without conflict.

How does cold welding work?

At first glance, the cold welding process might appear simple. But the process demands monastic precision. Here’s how it unfolds:

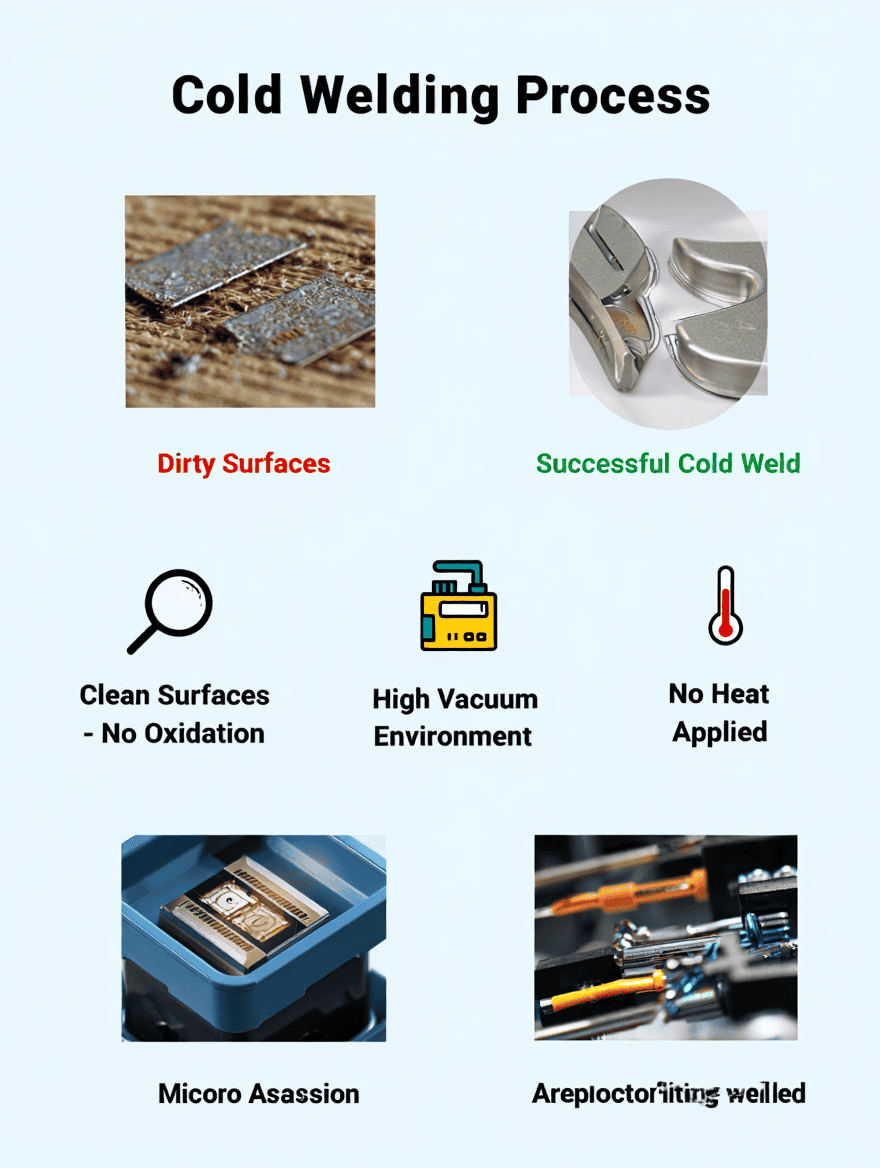

Surface Sanctification

The success of cold welding rests on surface purity. The oxide films and grime must vanish completely, often through meticulous brushing, scraping, or chemical cleansing. Some high-end operations even carry this out inside vacuums or inert chambers to guard against reoxidation.

Perfect Alignment and Pressure

Once cleansed, the metals are positioned with surgical accuracy and then pressed together under immense pressure, sometimes hundreds of megapascals. The aim is to make their surfaces touch intimately, atom-to-atom.

The Silent Fusion

Under this force, the metal deforms plastically, allowing atomic grids to interlace. No heat, no filler, just molecular fusion born from sheer force and purity.

The Many Realms of Cold Welding

Though it sounds like a laboratory marvel, cold welding lives a very real, practical life across industries, it’s found in:

- Electronics and Electrical Engineering: For joining conductive metals in circuitry, battery tabs, and wire terminations.

- Aerospace and Satellite Systems: In the vacuum of space, metals can cold-weld accidentally, a challenge engineers must design around.

- Microjoining and Nanotech: Where even a whisper of heat could ruin precision, cold welding becomes the savior.

- Foil and Composite Manufacturing: Perfect for bonding ultra-thin metal sheets without deforming them.

Why Cold Welding Captivates Engineers

- No Heat, No Distortion: Metals stay true to their original mechanical essence. No warping, no heat-affected zones.

- Friendly to Dissimilar Metals: Fusion welding struggles where cold welding thrives, while creating pure bonds between metals like copper and aluminum.

- Eco-Clean Process: No flux, no fumes, no filler. Just the clean honesty of physics at work.

- Bond Strength Beyond Sight: The joints often match the base metal’s own integrity, blending invisibly into a single body.

Yet, Not Without Its Demands

- Cold welding, for all its grace, is a demanding master:

- Insists on impeccably clean surfaces.

- Only entertains ductile metals.

- Needs precise, evenly distributed pressure.

- And it’s not the fastest. Here, surface prep takes time and care.

So while not a universal solution, it’s an extraordinary one, rewarding perfectionists with results that border on invisible craftsmanship.

Cold Welding in Today’s Fabrication Frontier

Modern fabrication shops, especially those in aerospace, pharmaceuticals, and electronics, have embraced cold welding not as a novelty but as a necessity. Where heat could distort or contamination could compromise, this process delivers purity.

These are not merely welders; they are engineers of silence, joining metals without chaos, relying on the discipline of cleanliness and precision instead of brute force and fire.

Cold welding teaches a poetic truth: not all strength is born in flame. Sometimes, the quietest forces like pressure, precision, and patience- forge the most enduring bonds.

In a world obsessed with spectacle, cold welding whispers a countertruth: you don’t need noise to create power. Just purity and persistence.

For the dedicated craftsperson who values precision and wants the cleanest, most controlled joins, cold welding is a quiet marvel, it’s proof that fusion can come from careful method and science, not just brute heat.