08

Oct

What Is TIG Welding?

TIG Welding (GTAW) is a process where a non-consumable tungsten electrode creates an arc that melts the base metal. The weld area is shielded from atmospheric contamination by an inert gas, typically argon. Unlike MIG welding, TIG doesn’t automatically feed filler metal, instead, the welder manually adds it, giving precise control over every joint.

Where TIG Welding Excels

- Automotive exhausts and engine parts

- Aircraft and aerospace fabrication

- Stainless steel handrails and kitchen fixtures

- Custom metal artwork and repairs

- Thin aluminum sheets and tubing

Essentially, anywhere you need clean, detailed, and strong welds, TIG is the go-to process.

How a TIG Welder Works (Step-by-Step)

At its core, TIG welding is a balance of heat, control, and shielding gas. Here’s how it works from start to finish:

| Step | Process | Purpose |

|---|---|---|

| 1. Power Supply Activation | A TIG welder uses a constant current power source. | Maintains a stable arc, ensuring consistent heat. |

| 2. Arc Initiation | The welder strikes an arc between the tungsten electrode and the workpiece. | Creates the heat needed to melt metal surfaces. |

| 3. Shielding Gas Flow | Argon or a mix of argon/helium is released through the torch. | Protects the weld from oxygen and nitrogen. |

| 4. Melting and Pool Formation | The intense heat forms a molten pool. | Allows fusion of metals for a seamless bond. |

| 5. Filler Rod Addition (Optional) | A filler rod may be dipped into the pool manually. | Strengthens and shapes the weld bead. |

| 6. Cooling Phase | The torch is slowly withdrawn while shielding gas continues to flow. | Prevents oxidation and ensures clean cooling. |

The result? A strong, visually flawless weld bead that requires little to no cleanup.

TIG Welding Equipment and Components

To master TIG welding, it helps to know the tools behind the torch.

- Tungsten Electrode: Non-consumable, made from pure tungsten or alloys like thoriated or ceriated tungsten.

- Torch: Holds the electrode and directs the shielding gas.

- Foot Pedal or Finger Control: Adjusts amperage for fine control over heat.

- Power Source: Provides DC (for steel, stainless steel) or AC (for aluminum, magnesium).

- Shielding Gas: Argon is the standard; helium is used for deeper penetration.

AC vs DC TIG Welding

| Type | Use Case | Advantages |

|---|---|---|

| DC (Direct Current) | Steel, stainless steel, copper, titanium | Smooth arc, deeper penetration |

| AC (Alternating Current) | Aluminum, magnesium | Cleans oxide layer, ideal for reflective metals |

When Should You Choose TIG Welding?

TIG welding shines when precision and appearance are non-negotiable. Here’s when it’s the right call:

Thin or Delicate Materials

- Perfect for metals under 3mm thick.

- Prevents burn-through common with MIG or Stick welding.

High-End or Aesthetic Projects

- Produces neat, shiny welds, ideal for visible parts.

- Common in architectural and artistic fabrications.

Corrosion-Resistant Applications

- Ideal for stainless steel and aluminum jobs that demand long-term durability.

Critical Structural Work

- In industrial or aerospace jobs where weld strength determines safety.

At RS Mobile Welding Service, TIG welding is used for everything from custom fabrication to on-site aluminum repair, delivering unmatched finish and performance.

Advantages and Limitations of TIG Welding

| Advantages | Limitations |

|---|---|

| Produces clean, spatter-free welds | Slower process compared to MIG |

| Ideal for thin materials | Requires higher skill level |

| No flux or slag cleanup | Equipment cost is higher |

| Precise heat control | Not ideal for dirty or rusty metals |

| Works on various metals | Not as fast for large projects |

While TIG welding isn’t always the fastest, it’s the best option when perfection matters.

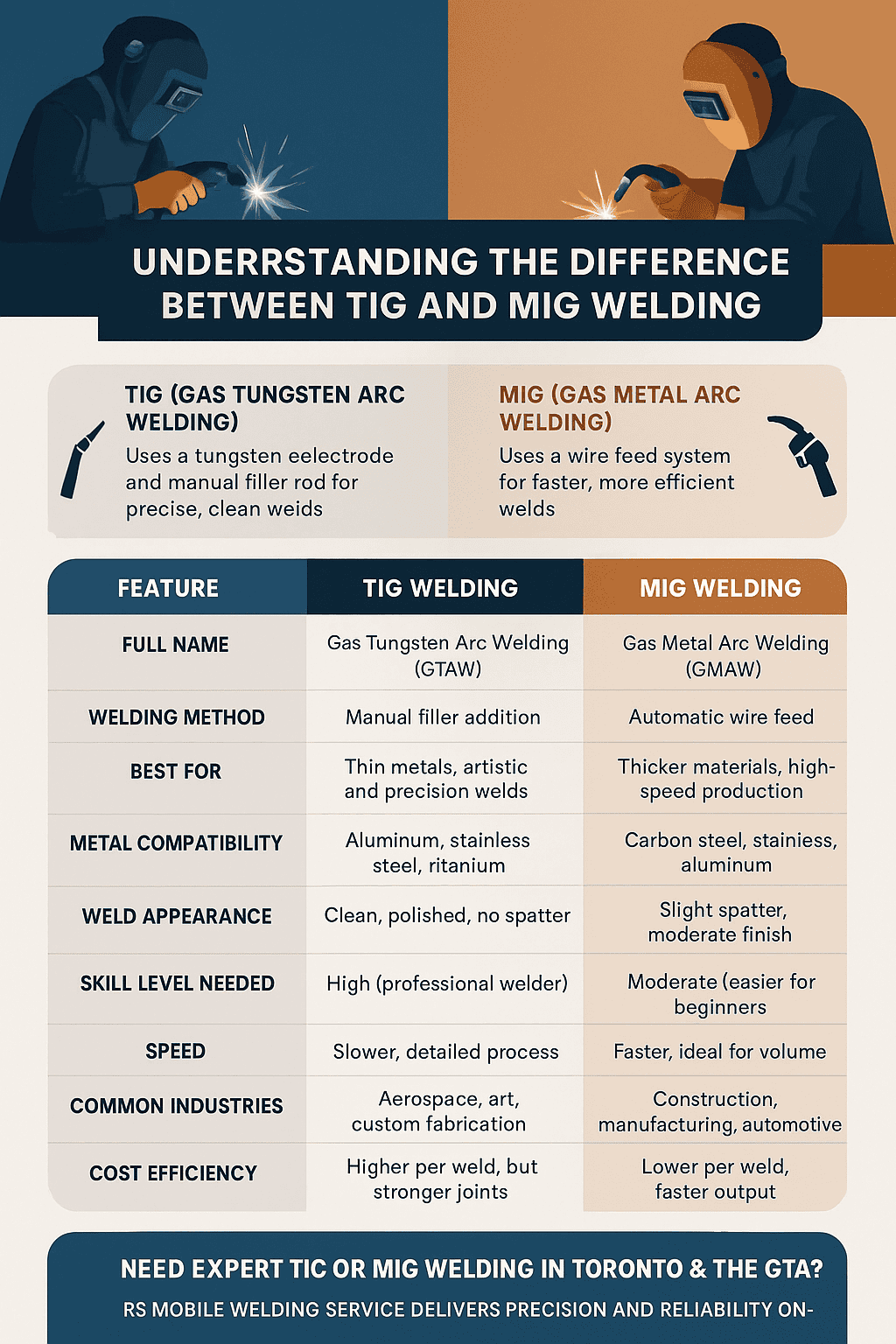

TIG Welding vs. MIG Welding: Which One Should You Choose?

| Feature | TIG Welding | MIG Welding |

|---|---|---|

| Welding Process | Manual filler addition with tungsten electrode | Continuous wire feed |

| Best For | Precision, thin metals, artistic welds | Speed, thicker materials, mass production |

| Cleanliness | No spatter or flux | Slight cleanup required |

| Ease of Use | Advanced skill required | Easier for beginners |

| Cost Efficiency | Higher cost per weld | Faster and cheaper for volume work |

| Appearance | Superior finish | Moderate finish |

👉 Need both options?

RS Mobile Welding offers TIG Welding Services and MIG Welding Services, ensuring your project gets the right technique for quality and budget.

👉 Get a free quote today for your next TIG welding project in Toronto or surrounding areas in GTA

Common TIG Welding Mistakes (and How to Avoid Them)

Even skilled welders face challenges. Here’s how to steer clear of the most common pitfalls:

- Contaminated Tungsten: Always keep tungsten clean and properly sharpened.

- Wrong Gas Flow: Too high = turbulence, too low = oxidation. Keep around 15–20 CFH.

- Incorrect Torch Angle: Maintain a 15–20° angle for smooth coverage.

- Overheating the Workpiece: Use the foot pedal to modulate amperage.

- Skipping Post-Flow: Let gas flow continue for 5–10 seconds after welding to protect the weld bead.

Professional TIG Welding in Toronto & the GTA

When precision, aesthetics, and durability matter, DIY solutions fall short. That’s where RS Mobile Welding Service comes in.

Why Choose RS Mobile Welding for TIG Projects in GTA

- Certified Welders: Trained and experienced in all metals including aluminum, stainless, and titanium.

- Mobile Service: Fully equipped units travel across Toronto and GTA for on-site TIG welding.

- Industrial & Commercial Expertise: From Structural Welding to pipe repairs and machine components, we deliver fast, professional results.

- Emergency Response: 24/7 availability to minimize downtime and restore productivity.

Whether it’s a small fabrication job or a complex industrial repair, TIG welding done by professionals ensures your investment lasts.

Final Thoughts: Choose TIG Welding for Precision That Speaks for Itself

TIG welding might not be the fastest or easiest process, but it’s unmatched in quality, control, and appearance. Whether you need a delicate aluminum repair or a flawless stainless-steel finish, it’s the method professionals trust.

If your project demands clean welds, long-term durability, and on-site service across Toronto and the GTA, RS Mobile Welding Service is ready to help.

👉 Get a free quote today for your next TIG welding project, and experience the precision difference.

Frequently Asked Questions (FAQs)

Q1. Is TIG welding stronger than MIG?

Yes – TIG welds generally offer stronger and more precise joints, especially on stainless steel and aluminum.

Q2. Can you TIG weld without gas?

No. The shielding gas is crucial to prevent oxidation and contamination of the weld.

Q3. What gas is used for TIG welding?

Pure argon is the most common. For deeper penetration, a mix of argon and helium may be used.

Q4. What metals can be TIG welded?

TIG works on stainless steel, aluminum, copper, magnesium, titanium, and bronze.

Q5. What metals should not be TIG welded?

Avoid lead, zinc-coated, or cast iron, they either release harmful fumes or don’t bond well.