Strength. Precision. Performance. Stainless Steel That Delivers.

We are the solution to every type of fabrication requirement you or your business has. Stainless steel is the most used metal in the food, medical, energy, chemical, and packaging industries. At RS Mobile fabrications, we provide a supreme-level finish when it comes to stainless steel fabrication, be it any kind of stainless steel components.

Our team strives to attain perfection through the fabrication job. Stainless steel, as the name suggests, is corrosion-proof; we ensure high-quality and durable fabrication, keeping such characteristics of the metal in mind. Our technicians hold expert-level skills when it comes to Welding and Fixturing.

Our experienced fabricators can minimize warping and distortion by using proper fixturing, preheating, and controlled Stainless Steel Welding techniques. We always use the best quality materials and the most high-performing tools. We make sure the final product is free of warping or any distortion while making it durable, affordable, and easily usable.

Overview of Our Stainless Steel Welding & Fabrication Services

The fabrication services we offer bring customization, top-notch quality, and timely delivery. Our well-finished products can turn out to be the exact solution your commercial operations need. Stainless steel welding and fabrication services are extremely useful for every kind of industry sector, from building components that are anti-rust, to making frames and tools for the food industry, such as large kitchens for mass production.

Stainless steel has established itself as a highly useful, rust-proof, and sturdy material. Its usability is astonishing, which makes it a metal that needs to go through quite a lot of fabrication procedures. Stainless steel fabrication methods include cutting, bending, welding, and shaping, followed by finishing. It involves the use of specialized equipment and techniques to create products that meet specific design and performance requirements, considering that stainless steel is built differently with its heat resistance and additional durability.

The metal is known for its long-lasting strength, aesthetically pleasing appearance, resistance against moisture, and extreme temperatures. On top of that, the metal has shown a very wide range of usability, from utensils, giant tools in the food industry, to the chemical industry, and from automotive to pharma, the metal has immense potential to make operations smoother. Stainless steel can build kitchen equipment, railings, tanks, structural frames, etc, through fabrication. In places where contamination is a major threat, stainless steel is a great option to consider, owing to its level of hygiene. To avail custom, high-quality, and punctual fabrication services in any metal, fetch us by searching stainless fabrication near me.

Ready to discuss your project?

Contact us today for a free consultation and quote.

What We Fabricate

- Stainless Steel Welding

We have expertise in a range of welding techniques to suit every application:

TIG Welding

TIG Welding

TIG stands for tungsten inert gas welding. Welding is a crucial part of the fabrication process, and TIG is one of the most impactful and efficient ways of welding. It joins two separate stainless steel pieces into one with precision and ensures durability. TIG offers clean, high-quality welds, especially on thin or decorative stainless steel material.

MIG Welding

MIG Welding

MIG welding uses the gas metal arc welding method. This welding method is more feasible for heavy and large-sized metal tools that need adhesion. MIG offers a very quick yet efficient turnaround with promising strength.

Spot Welding

Spot Welding

Perfect for joining sheet metals, commonly used in enclosures, panels, and assemblies. Our welders are certified and experienced, ensuring every joint is structurally sound and visually appealing.

Custom Steel Fabrication

Custom Steel Fabrication

We understand how every project, every client would require different specifications. Our skilled and licensed technician will assess and keep your steel fabrication requirements in mind and will work closely with you to offer custom stainless steel components and assemblies. Our team is perfectly capable of Custom Steel Fabrication, and their skillset is versatile enough to customize and develop detailed designs that fulfill your requirements.

Precision Cutting & Forming

Precision Cutting & Forming

We make sure to use state-of-the-art equipment like CNC plasma, laser, and waterjet cutting equipment to ensure accuracy while dealing with highly detailed projects.

Surface Finishing (Polishing, Passivation)

Surface Finishing (Polishing, Passivation)

Finishing is what gives the steel components the aesthetic appeal they need, with polishing and Passivation, we strive to achieve that.

- Polishing: Achieve mirror-like or satin finishes for architectural and food-grade applications.

- Passivation: Enhance corrosion resistance by removing contaminants and restoring the chromium oxide layer on stainless steel.

- Prototyping and Large-Run Fabrication

Whether you need a single prototype to test your design or a full production run, we have the capacity and flexibility to deliver. Our prototyping services help you refine your ideas before committing to large-scale manufacturing, saving time and resources.

Our Fabrication Process

Our wholesome yet streamlined process of fabrication includes various stages. The final product will go through multiple finishing procedures and testing before we deliver.

Consultation & Design

The process begins with our client’s visit or a call to know more about our metal fabrication and welding services. This is where our experts get a deeper understanding of our client’s needs. We offer all the possible solutions and services according to the requirements of the client. We ensure that our clients have access to the best possible material and methodology to receive their desired result.

Engineering & Planning

We initiate once we have a clear picture of the final product. We derive plans and blueprints in order to start working on them. Our team prepares detailed drawings and plans, optimizing for usability and cost-efficiency.

Fabrication

Here comes the execution part, where we cut, weld, and shape the stainless steel components according to the requirements and vision of the client. We make sure that the refined final product serves to your exact specifications.

Quality Control

Our technicians run all the components under rigorous inspection to ensure they meet our high standards. This enables us to remain the first choice of our clients, as this process helps us make durable and functioning designs.

Delivery & Installation

Our timely delivery and fast turnaround are owed to our dedication to follow the schedule and remain punctual. In special cases, we provide on-site installation to ensure your project is completed on time and to your satisfaction.

Why Choose Us as Your Steel Fabricator

-

Experience

Experience

Our thorough 20+ years of fabrication experience has put us on the front line of the business; we are proud and leading steel fabricators in Toronto and the GTA. State-of-the-art welding equipment

State-of-the-art welding equipment

Investing in world-class machinery to function properly is what we believe in. We rely on the latest CNC machinery and welding technology for unmatched precision and efficiency.

-

Fast turnaround times

Fast turnaround times

Your busy schedule and deadlines are crucial to us. We take the time seriously and ensure rapid turnaround. Serving commercial and residential clients

Serving commercial and residential clients

Serving both commercial and residential clients, we adapt our services to projects of any size or complexity.

Industries Served

Our stainless steel fabrication services support a wide range of industries, including:

- Architecture & Construction: Balustrades, handrails, cladding, and structural components.

- Food & Beverage: Hygienic work surfaces, equipment, and storage solutions.

- Pharmaceutical & Medical: Cleanroom furniture, enclosures, and laboratory fixtures.

- Manufacturing & Industrial: Machine frames, tanks, and process piping.

- Hospitality & Retail: Custom fixtures, signage, and decorative elements.

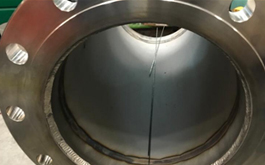

Portfolio / Gallery

Testimonials

Book now before our calendar fills up, and get a free quote for your project!

All set to get your fabrication needs fulfilled? Get in touch with us today. We are skilled and devoted to bringing your stainless steel project to life.

Call us on (416) 825-2956 or

write us at Rs.Welding@hotmail.com for all your queries.

Steel Fabrication Frequently Asked Questions (FAQs)

What types of steel do you work with?

We fabricate using various steel types including mild steel, stainless steel, and structural steel. Each material is selected based on your project’s load, durability, and finish requirements.

Can you handle large-scale industrial fabrication projects?

Yes, we have the capacity and experience to manage small to large-scale industrial steel fabrication, including heavy-duty components, structural frameworks, and high-volume production runs.

Do you provide custom steel cutting and bending services?

Absolutely. We offer precision cutting, bending, and forming using advanced CNC machinery to meet detailed specifications for custom steel components.

Is installation can be included in your steel fabrication services?

Yes, we offer full-service fabrication including delivery and professional on-site installation to ensure everything fits and functions perfectly.

What quality control measures do you follow?

We follow strict quality control protocols at every stage—design, cutting, welding, and finishing—ensuring compliance with CSA, CWB, and industry-specific standards for safety and durability.

Do you handle both structural and decorative steel fabrication?

Whether it’s heavy-duty structural work or custom decorative pieces like railings and signage, we have the tools and talent to bring your vision to life.

Can you fabricate steel components that meet CSA W47.1 and W59 standards?

Our shop and welders are fully certified under CSA W47.1, and all fabrication adheres to CSA W59 welding standards to ensure compliance and long-term durability.

Which areas do you provide custom welding and steel fabrication?

We offer steel fabrication services in Toronto, Mississauga, and surrounding areas in GTA. Contact us today for free cost-estimate.

Do you work with general contractors near by or project managers on site-specific builds?

Yes, we collaborate with local contractors, site supervisors, and project managers to ensure your steel components are fabricated and installed according to schedule and site logistics.

Our Certifications

CWB

Canadian Welding Bureau

CSA-Standard W47.1

I had a small job done recently and the welding was perfect. I got exactly what I had asked for and the price was extremely good. Also, the job was done right away as I waited. I will definitely return with other jobs and would recommend RS Mobile Welding Services to anyone requiring welding/fabrication work.

BERT MORIN

The Best welder I have dealt with 🙂 Raj (at the shop) was professional and very helpful, great prices and I will definitely use rs mobile welding again. Thank you